Over 3,000 sold COMS units in use worldwide

used by leading plant manufacturers since 1972

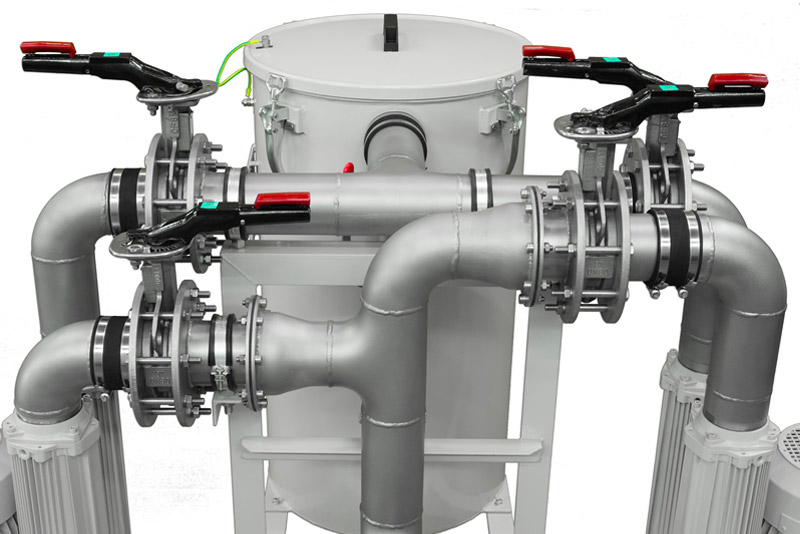

Oil mist separators

Standard and special designs

Standard designs

Blower throughputs of 8 to 255 Nm3/h at 50 Hz operation, -60 mbar Δp

- All compact series with filter housings

- Filter element efficiency of 99.98%

- The purified air has been verified to have a residual oil content of below 0.1 mg/m3 and contains no particles between 0.2 and 0.9 μm.

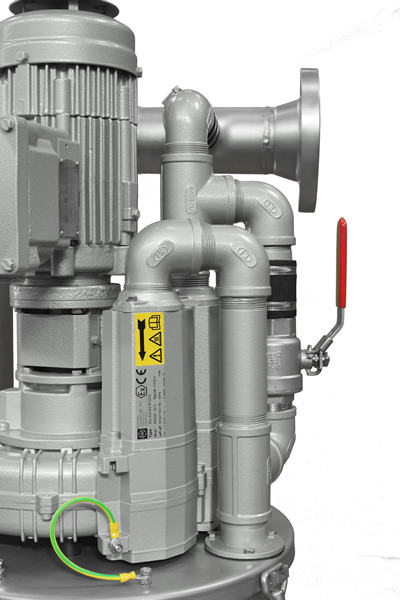

- Space-saving design with a motor blower unit mounted entirely on the cover

- Made of construction steel, entirely hot-dip galvanized and the exterior painted

- Internal parts made of aluminum

- Filter elements made of fiberglass fleece with inorganic binder

- Compressor motor 230/400 V, 50 Hz, protection class: IP55

- Quick spare part supply secured for years to come

- ATEX design for applications up to Zone 2 (3/3G)

Special designs

Blower throughputs of 340 to 1,200 Nm3/h at 50 Hz operation, -60 mbar Δp

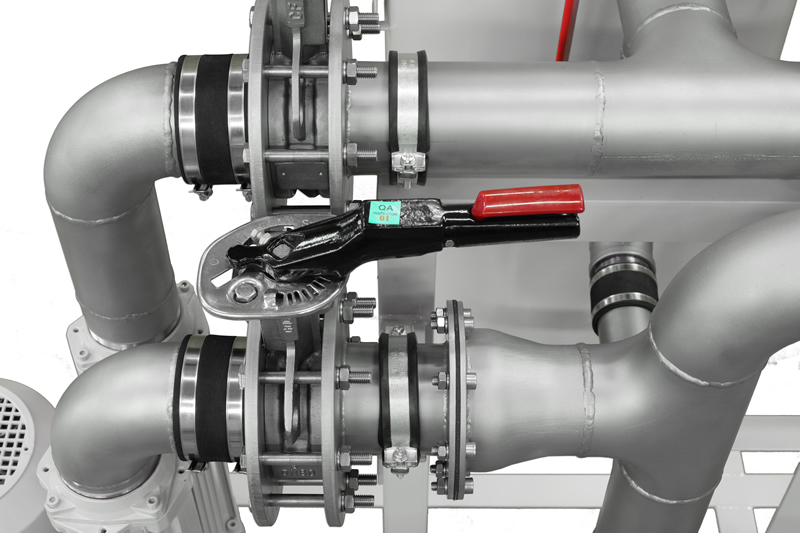

- Project-specific process connections

- Without side channel compressor

- Materials: carbon steel, 304/304L and 316L stainless steel

- Special painting for offshore applications, for example

- The entire Contec oil mist separator is certified according to ATEX Directive 2014/34/EU and can be used in areas subject to explosion hazards

- Complies with cutting-edge safety standards

- Can be used in gaseous atmospheres as Category 2 and 3 equipment (Equipment Group II)

- Upon request, can be manufactured according to ATEX requirements for Zone 1 (occasionally explosive atmosphere) or Zone 2 (explosive atmosphere not likely to occur in normal operation and if it does occur, persists for a short period only) of Group IIC (propane, ethylene, hydrogen)

- Ex-pressure resistant drives, VIK, special voltages, etc.

The advantages of Contec Oil Mist Separators (COMS)

- Oil mist separator can be installed in gas and steam turbines, hydroturbines, gas and diesel engines, turbo-compressors, generators, gearboxes and other rotating machinery

- Filter efficiency of 99.98% with droplets of 0.1 µm

- No particles between 0.2 μm und 0.9 μm

- Individual connections design for direct integration of the oil mist separator into the existing systems

- Individual manufacture with blower throughputs of 8 to 1,200 Nm3/h at 50 Hz operation and -60 mbar Δp

- Modular system for virtually any application

- Approved and proven oil mist separators on systems from Siemens, MAN Energy Solutions, Dresser Rand, Mitsubishi, Hitachi, Toshiba, GE, Alstom and many more

- Numerous options

- Quick spare part supply secured for years to come

- Long service life and simple filter element replacement

- Automatic oil return with sight glass monitoring

- Awarded with the environmental technology prize

The oil mist separator is installed in lubricating oil tanks for:

- Turbines

- Gas and steam turbines

- Turbo-compressors and turbo-machinery

- Gas and diesel engines

- Vacuum pumps

- Rotating machinery

- Large-scale compressors

- Crank shaft gears

- Generators

- Other machinery with oil systems

Contec Oil Mist Separator series

| COMS-Type | Throughput | kW engine |

|---|---|---|

|

24 Nm3/h |

0.18 kW |

|

|

50 Nm3/h |

0.37 kW |

|

|

110 Nm3/h |

0.75 kW |

|

|

190 Nm3/h |

1.10 kW |

|

|

255 Nm3/h |

2.20 kW |

|

|

3,000/630 |

360 Nm3/h |

2.20 kW |

|

3,000/762 |

340 Nm3/h |

3.00 kW |

|

4,000/630 |

480 Nm3/h |

3.00 kW |

|

5,500/762 |

600 Nm3/h |

4.00 kW |

|

7,500/762 |

710 Nm3/h |

5.50 kW |

|

8,000/762 |

950 Nm3/h |

9.20 kW |

|

9,200/762 |

1,200 Nm3/h |

11.00 kW |

How do oil mist separators work?

Have a look at the animation to see the interior of a COMS (Contec Oil Mist Separator). How are oil aerosols separated and fed back into the system, where are the filter elements and how are they replaced?