Level measurement

Whether analogue or digital - we configure the suitable solution

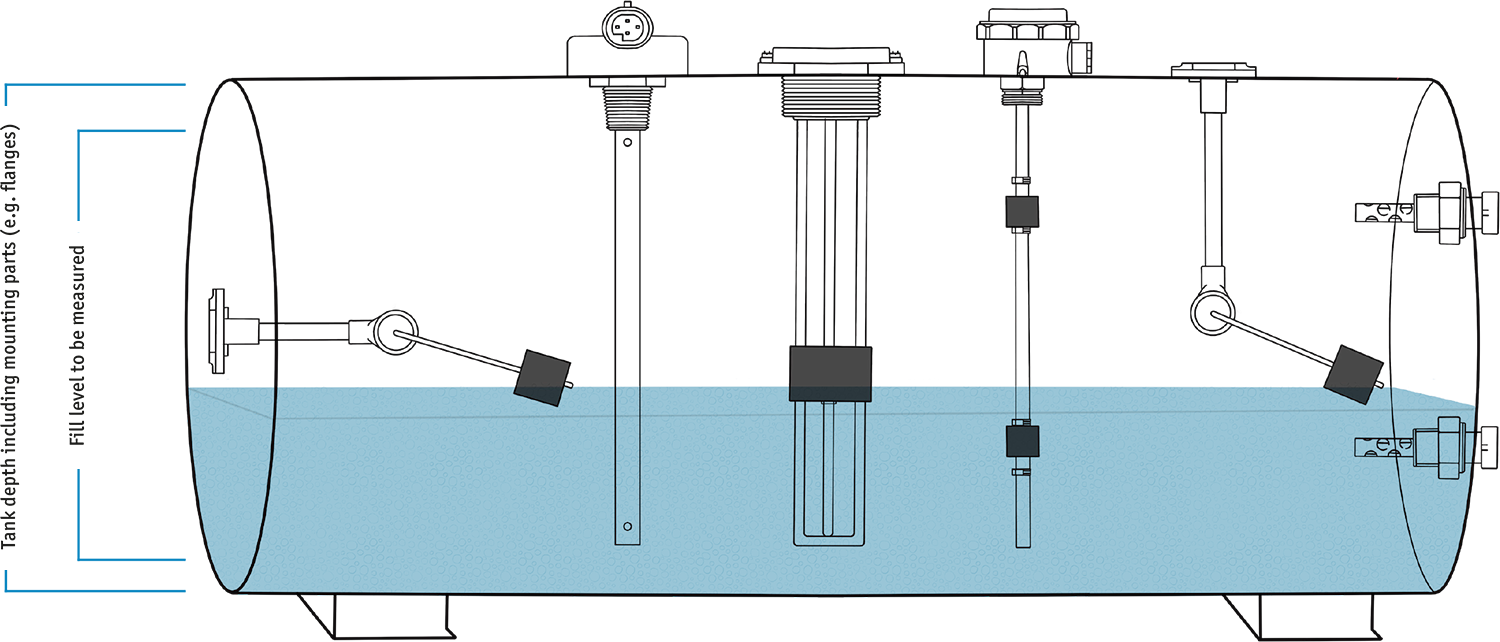

For exact monitoring of fill levels and temperatures, Contec offers a number of components that reliably measure and regulate even in changing media and explosive atmospheres, or as part of applications in such environments.

All sensors, fill level indicators and float switches are designed and manufactured according to customer specifications. Within the realm of technical feasibility, we design the right solution according to the required application parameters such as output signal; position, number and function of switching points; immersion depth; and material.

Clear information is the foundation specialists use to make sound decisions. That makes clarity and reliability in determining fill levels indispensable: clarity about one's own actions and reliability expected from the technical components. The extensive Contec measuring device portfolio provides just that.

Contec measuring devices can be used to measure, regulate and monitor the following:

- Oils

- Fuels

- Other liquids

Typical applications areas:

- Construction of structural components such as storage tanks

- Pump and compressor construction

- Detector in fuel tanks for commercial and construction vehicles

- Large inkjet printing systems

- Railway and shipbuilding industries

- Reservoirs and storage tanks for liquids

The standard Contec series of float switches, fill level indicators and sensors are manufactured according to customer specifications. Material, immersion depth, tension, output signal, number and function of switching points, etc. are freely configurable within technical capabilities.

- Reed relay float switch

- Level indicator

- Fill level sensors

- Laterally mountable float switch

- Hydrostatic fill level indicator

- Capacitive level indicator

- Mechanical fill level indicator

CHARACTERISTICS OF CONTEC COLM FILL LEVEL MEASUREMENT TECHNOLOGY:

- Precise, reliable fill level measurement

- Functional precision even with changing media

- Fields of application with oils, fuels, acids, lyes, and other liquids

- Configurable parameters for sensors,

- Indicators, and switches

- Extensive standard product range as well as customized solutions

- Robust industrial quality

CONTEC COLM FILL LEVEL MEASUREMENT TECHNOLOGY PRODUCT RANGE OVERVIEW:

- Fill level sensors (capacitive/electromechanical)

- Fill level indicators (digital/analog/radar-guided)

- Fill level switches

- Temperature switches

Collaboration with Contec confirms that quality is not confined to the product side. Technical support and the variety of Contec products give us and our products success.

Manuel Albrecht, Technical Head of Tank Technology, Rietbergwerke GmbH & Co. KG

Reliable testing, professional transaction, on-time delivery. That is what we stand for.

Sensors, switches and indicators

For exact monitoring of fill levels and temperatures in engines, engine cooling systems, concrete pumps, diesel generator sets, etc., Contec offers a number of sensors, indicators and temperature switches whose design, electrical connection options, etc. may vary.